Şekillendirme Makinesi Galvanizli Çelik Konteyner Güverte Rulo

Son Fiyat alın| Ödeme şekli: | L/C,T/T |

| Incoterm: | FOB,CIF |

| Min. sipariş: | 1 Set/Sets |

| Ulaşım: | Ocean |

| Liman: | Tianjin Port |

| Ödeme şekli: | L/C,T/T |

| Incoterm: | FOB,CIF |

| Min. sipariş: | 1 Set/Sets |

| Ulaşım: | Ocean |

| Liman: | Tianjin Port |

model numarası.: XF30Container Deck Roll Forming Machine

Marka: XF

| Satış Birimleri | : | Set/Sets |

| Paket Türü | : | Yüklemek için profesyonel teknisyenlerimiz Mal yükünü herhangi bir zarar vermeden konteynere teslim eder. |

The file is encrypted. Please fill in the following information to continue accessing it

Botou Xianfa Rulo Şekillendirme Makinesi Fabrikası

Fabrikamız 1996 yılında kurulmuştur, biz rulo şekillendirme makinesi fabrikada profesyonel.

Ana ürünler trapez sac rulo şekillendirme makinesidir

oluklu levha rulo şekillendirme makinesi, sırlı çini rulo şekillendirme makinesi, çift katmanlı rulo şekillendirme makinesi ......

Biz ISO9001 kalite sertifikası ve Avrupa CE güvenlik sertifikası geçti.

Ürünlerimiz Kuzey / Güney Amerika, Asya, Afrika, Avustralya ve dünya çapında satıldı

Avrupa...

Farklı bölgelerdeki müşterilerin gereksinimlerini iyi biliyoruz.

İsteğinizi dinlemek için olağanüstü bir ihracat ekibimiz var; Tasarlanan ekip, isteğinize göre size en iyi teklifi gösterecektir.

İşbirliğimizin parlak bir gelecek yaratacağına inanıyoruz

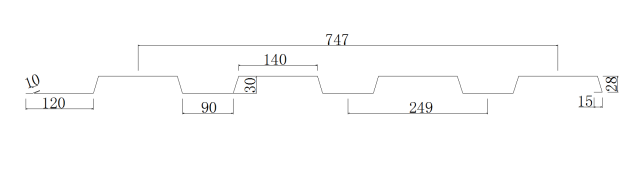

Şekillendirme Makinesi Galvaniz Sac Rulo Güverte Rulo

Ekipman Detaylı Parametreler

|

No |

|

|

|

1 |

Suitable Material |

Colored Steel plate, Galvanized Board |

|

2 |

Width of the raw material |

1219mm |

|

3 |

Rows of rollers |

18Rows |

|

4 |

Appearance size |

9800*1550*1510mm |

|

5 |

Total power |

11+11+5.5KW |

|

6 |

Thickness of raw material |

1.2-1.6mm |

|

7 |

Productivity |

0-10m/min |

|

8 |

Diameter of shaft |

¢80mm |

|

9 |

Voltage |

380V 50Hz 3phases |

|

Manual Uncoiler

|

Usage:It is used to support the steel coil and uncoil it in a turnable way. The steel coil is uncoiled by hand. Loading capacity:5000KG.Inner diameter: 500-508mm |

|

Main Roll Forming Machine

|

Material of rollers: shaft bearing steel(quenching)The polished surface and the heat treatment towards the molds also can keep the molding plate surface smooth and not easy to be marked when it is being stamped. |

|

Hydraulic System AND Computer Control Cabinet

|

Hydraulic oil: 40# hydraulic oil into the hydraulic oil tank ,the pump drive the cutter machine to begin the cutting job. The target piece`s length is adjustable and digit of it can be adjusted. Computed mode has two modes: automatic and manual one. The system is easy to operate and use PLC: EURA(Can customize as customer require) |

|

Shearing Mechanism

|

It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products. Material of blades: Cr12,quenching treatment |

|

Output Table

|

It adopts welded steel and supported roller to transmit the products,which is used to collect the finished products. |

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.