Büyük açıklıklı kemer şekillendirme makinesi

$40000≥1Set/Sets

| Ödeme şekli: | L/C,T/T,D/P |

| Incoterm: | FOB,CFR,CIF |

| Min. sipariş: | 1 Set/Sets |

| Ulaşım: | Ocean,Land |

| Liman: | Tianjin New Port |

$40000≥1Set/Sets

| Ödeme şekli: | L/C,T/T,D/P |

| Incoterm: | FOB,CFR,CIF |

| Min. sipariş: | 1 Set/Sets |

| Ulaşım: | Ocean,Land |

| Liman: | Tianjin New Port |

model numarası.: XF914 Large Span Arch Forming Machine

Marka: Xf

Uygulanabilir Endüstri: Yapı Malzemesi Mağazaları

Barrant Dışı Hizmet: Çevrimiçi destek, Yedek parça, Video Teknik Desteği, Saha Bakımı ve Onarım Hizmeti

Yerel Hizmetler Nerede Sağlanır (Hangi Ülkelerde Yurtdışı Servis Outlets Var): Hiçbiri

Showroom Konumu (hangi ülkelerde Yurtdışında örnek Odalar Var): Hiçbiri

Eski Ve Yeni: Yeni

Makine Tipi: Karo oluşturma makinesi

Fayans Tipi: Çelik, Renkli çelik

Kullanmak: Çatı

Verimlilik: 15 m/dakika

Anavatan: Çin

Garanti Süresi: 1 yıl

Çekirdek Satış Noktası: Kullanımı kolay

Haddeleme: 0.3-0.8mm

Besleme Genişliği: Başka

Mekanik Test Raporu: Sağlanan

Video Fabrikası Denetimi: Sağlanan

Pazarlama Türü: Yeni Ürün 2020

Çekirdek Bileşen Garanti Süresi: 1 yıl

Ana Bileşenler: Plc

Sertifika: ISO

Kullanım: Çatı

Özelleştirilmiş: Özelleştirilmiş

İletim Yöntemi: Hidrolik basınç

Kontrol Sistemi: PLC Kontrolü

İşlem Için Uygun: Renkli çelik plaka

Kullanmak: Çatı döşemesi

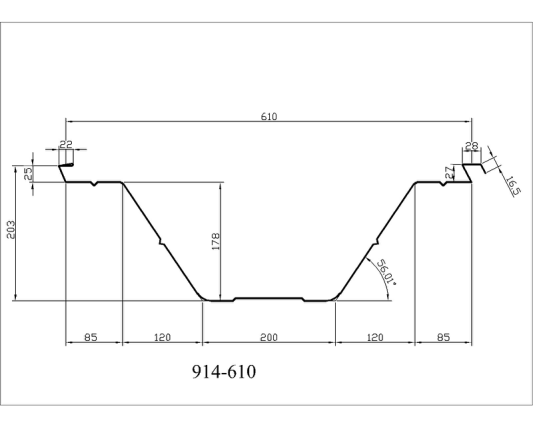

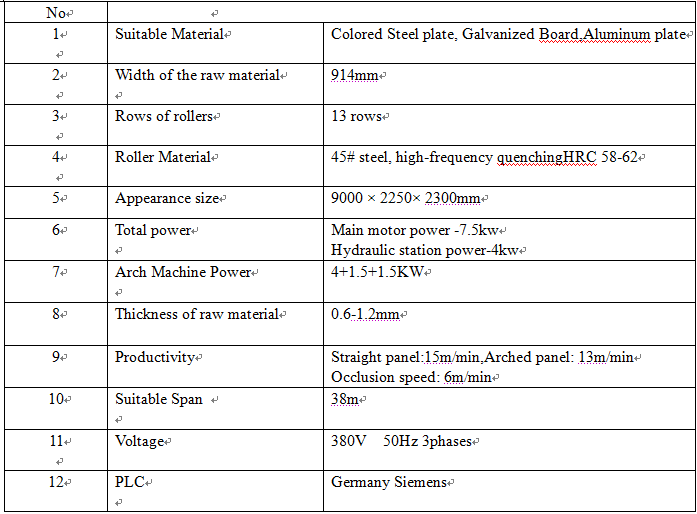

Thickness Of The Plate: 0.8-1.2mm

Width Of The Plate: 914mm

Using The Area: 610mm

Voltage: 380V 50Hz 3phases(Can Be Customized)

| Satış Birimleri | : | Set/Sets |

| Paket Türü | : | Mal yükünü herhangi bir hasar olmadan kabın içine garanti altına almak için profesyonel teknisyenlere sahibiz. |

| Resim Örneği | : |

|

The file is encrypted. Please fill in the following information to continue accessing it

Color Steel Sheet 914 Large Span Arch Forming Machine

Arch Forming Machine, Curving Roll Forming Machine, Large Span Bending Forming Machine

There are two kinds of Metal Forming and Arch Machine, one is no beam, another used for roof with beam.The feeding width of coils for Large Span Arch Machine is 914mm. There are two functions of Steel Panel Arch Machine, one is to get straight sheet, another is to get arch sheet.

914 Large Span Arch Forming Machine Component Specification

1.Manual Uncoiler

Usage: It is used to support the steel coil and uncoil it in a turnable way. The steel coil is uncoiled by hand.

Loading capacity: 5T, Inner diameter: 500-508mm

2.Main Roll Forming Machine

Material of rollers: 45# steel, roller surfaces polishing, hard plating.

The polished surface and the heat treatment towards the molds also can keep the molding.

Plate surface smooth and not easy to be marked when it is being stamped

3. Hydraulic System

Power: 11KW, Hydraulic oil:40#.

Hydraulic oil into the hydraulic oil tank, the pump drives the cutter machine to begin the cutting job.\

4. Shearing Mechanism: It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products.

Material of blades: Cr12, quenching treatment.

5. Computer Control Cabinet: The target piece`s length is adjustable and digit of it can be adjusted.

Computed mode has two modes: automatic and manual one. The system is easy to operate and use

6.Entry Beach: Put the raw material (steel plate) through the beach to manufacture and process, it can guarantee that the products are neat

parallel and everything is uniformity.

7.Hydraulic Station: It is controlled by gear wheel oil pump.

After filling the hydraulic oil into the hydraulic oil tank, the pump drives the cutter machine to begin the cutting job

Hydraulic oil: 40#. Components: The system includes a set of hydraulic tank, a set of hydraulic oil pump, two hydraulic pipes.

8. Encoder: One counter gauges length, pulses and decides length. Seamer: It`s used to seam the panels.

1.We have professional technicians for loading

Guaranteed the goods load into container without any damage.

2. Transportation : Machines need one 40 feet container to hold

3.Please provide us the nearest port name, we will ask shipping cost and arrange shipping for you

Ödeme şekli:

Method 1:30% deposit by T/T in advance and 70% balance after inspection confirmation before shipment

Method 2:L/C is also acceptable.

Installation, Commissioning, Test and Training

1. The engineers from the Seller shall supervise the installation on site and fulfill the commissioning.

They should start off within 10 days after they get the information from the Buyer.

2. The Buyer shall pay for the international air tickets and the local, such as board and lodging, daily transportation, communication,Insurance,

etc. The Buyer shall pay USD 100 /day /person to the Seller for the commissioning.

3. The Buyer shall prepare an interpreter for better communication between the two sides.

Looking for ideal Roofing Roll Forming Machine Manufacturer & supplier ? Yaratıcı olmanıza yardımcı olacak harika fiyatlarla geniş bir seçimimiz var.

All the Roofing Roll Forming Machine are quality guaranteed. We are China Origin Factory of Roll Forming Machine

Herhangi bir sorunuz varsa, lütfen bizimle iletişime geçmekten çekinmeyin.

Product Categories :Manufacturing & Processing Machinery > Building Material Making Machinery > Tile Making Machine

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.